East Campus Build 2023

I talk about my experience at the 2023 annual MIT East Campus build effort. I helped out for a little bit during my visit to Cambridge a few weeks ago.

Preview

Introduction

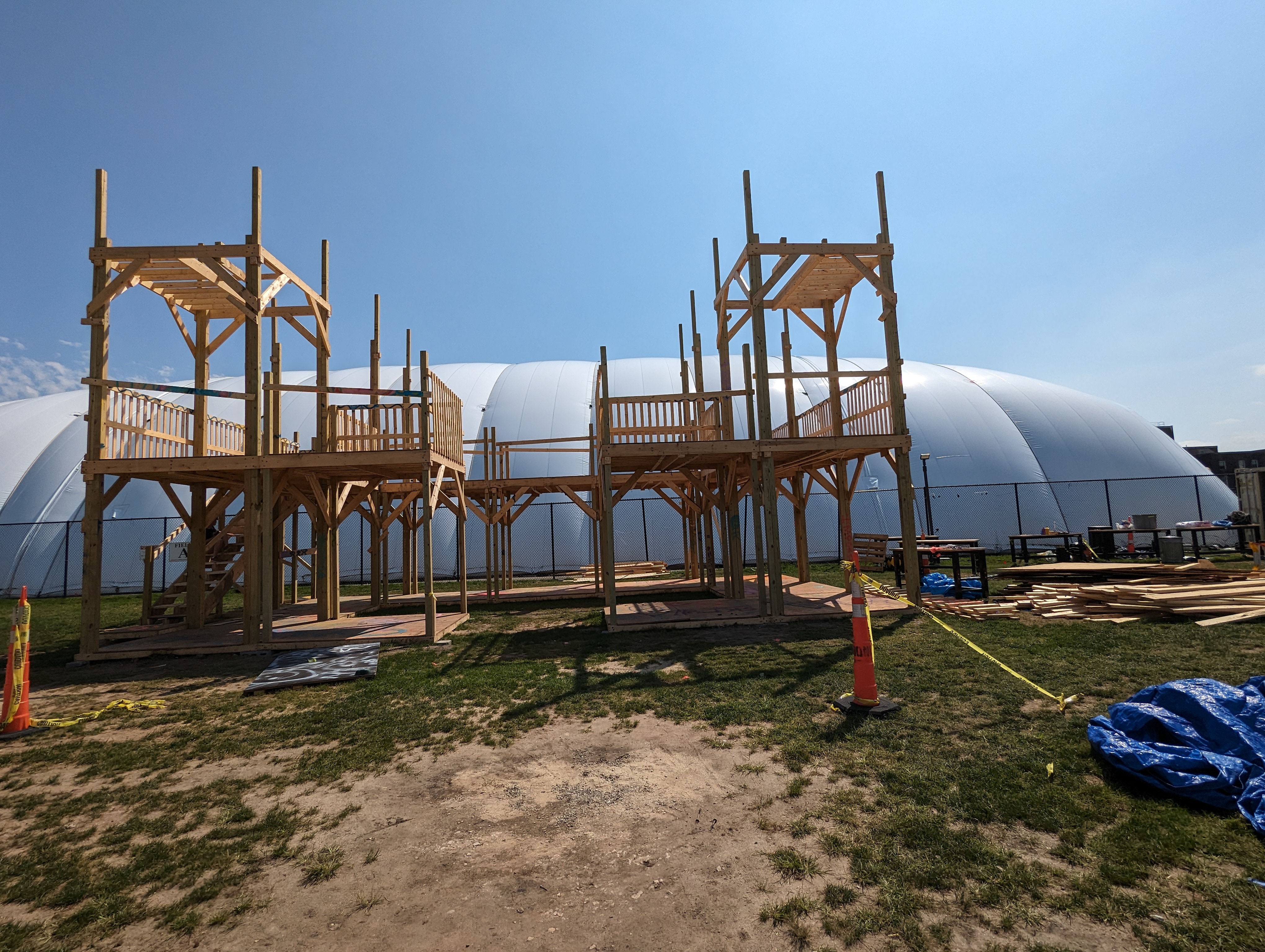

Every year since 20041, the students of MIT’s East Campus dormitory (EC) have built and disassembled a large wooden structure as a monument to the community. Last year, it was a climbing wall fort and rollercoaster.2 This year, it was a double climbing wall and a three-story fort.

Usually, the EC build happens in the courtyard between the two parallel buildings of East Campus. It happens during the few weeks before fall classes start, and it’s partially meant to drum up excitement among the incoming first-year students. What a marvelous sight, moving onto campus for college and seeing students building something so grand next to their dorm, of their own design, and all by themselves!

Things are different in 2023 because the physical dorm itself has become a construction site, having just started its 2-year renovation project that runs from Summer 2023 through Summer 2025. Instead, the community was granted permission to use the field next to the tennis bubble as a build site.

One up-side is that the build site is much closer to dorm row. It’s easier to do external outreach this way since students moving into most of the dorms can see and hear the build. They might otherwise only find out about it through word-of-mouth, since East Campus is on the other side of campus.

One major down-side is that the people primarily working on the project need to commute way farther to get to it. Mustering up student labor to complete the project has historically been hard enough in normal times. It was much easier to get masses of people involved when the build was less than two hundred feet away from their bedroom.

I only helped out for a few days during my visit to Cambridge this year. Many of my friends were working on build, and I expected that they would appreciate the extra hand. I was much more involved with build for 2021 and 2022, and I always remember us being shorthanded.

This year, I helped out for about 15-20 hours total between building, monitoring for East Side Party, and deconstructing.

Background

I’ve never been very involved in the planning process for build. Usually there are a few head engineers who do much of the planning. They write up the designs and these get signed off on by several school offices and a professional engineer. They also do procurement for the materials and equipment. Some others raise funds through sponsors, though much of the money sometimes comes from the dorm house tax.

This year, like last year, the head engineer was my friend Anhad Sawhney ‘25.3 There are loads of pictures and CAD models available on his website, both of this year’s and of last year’s builds. There was also a team of build leads who were formally in charge of leading the build effort during the weeks when we’re cutting wood, assembling the build, and taking it down. I don’t remember all of them, but the most significant one I remember was Jordan P.A ‘24, who was on site day-in, day-out, putting in major sweat and hours to keep the project on track.

It takes so many person-hours to successfully complete the EC Build. It takes the student engineers months of preparation, but it also takes many students many hours to do the actual labor of carrying, cutting, screwing together, and eventually unscrewing the wood. It’s not particularly glamorous work, but you really can’t simply think up a fort and have it manifest itself. It takes major hours and major elbow grease. And it can be hard to get that from a labor pool of MIT students who might not be accustomed to getting their hands dirty with physical labor, especially on hot August days.

Construction

This year, I helped with the stairs, some miscellaneous tasks that simply needed doing, and, as a reasonably experienced builder, some minor people support.

Stairs

The stairs were a pain point in this year’s build, so I was part of the team working on getting them up. I helped screw in about half the tread 2x4s and began cutting the plywood risers that would stop people’s toes from going too far past each stair. A full build is many, many medium sized tasks that are split into little tasks. And every single one of them needs to be done to complete the build.

People Support

I don’t have any pictures for this part, but an understated part of the build process is being able to make good use of the available labor. Many times, first-years would come up, interested in the project and maybe even interested in helping out. But they don’t stick around for long unless they have the appropriate guidance.

Several times during the build, I stopped to make sure that the people who were showing up were being taken care of. If they wanted to help, I would find them someone more experienced who could do with a hand. Optimally, it would be for tasks that the newcomer would be excited about. On the other side, sometimes when a team was short-handed, I would go out and try to find the people who could come help. There were no formal structures in the build for these people-support kind of things; it was more holistically seeing where people were and where people needed to be. In the weeks before classes, there are people floating around for all sorts of reasons. And I like meeting with people.

In previous years, I would spend some time doing some outreach trying to get more people to build. Sometimes, I would be like a little foreman. People would be part of my crew and we would collectively work on a task like building trapdoors or building railings. There’s another thing: I could keep my nose down and just do the physical tasks that needed doing, but I could also get more person-hours onto the project by making sure that the right people were in the right places. It’s kind of like the capital versus consumer goods that they teach in microeconomics with the production-possibility frontier. There’s a balance between time spent directly on building versus on expanding the team.

We also had a scaled-down grilling operation this year, in part because this year’s labor force was scaled down. In previous years, I would also be one of the runners getting food (what we call rush burgers) from the grills to the builders. It was a good way to keep morale up when I was too tired to continue hauling or screwing things in.

Miscellaneous Tasks

I helped with a few things that just needed doing.

One of the things that’s almost always needed is hauling: just carrying things from point A to point B. Wood needed to be carried from the pallets to the saws; mattresses needed to be carried from the loading point to the climbing walls; just all sorts of things needed to be carried from somewhere to somewhere else.

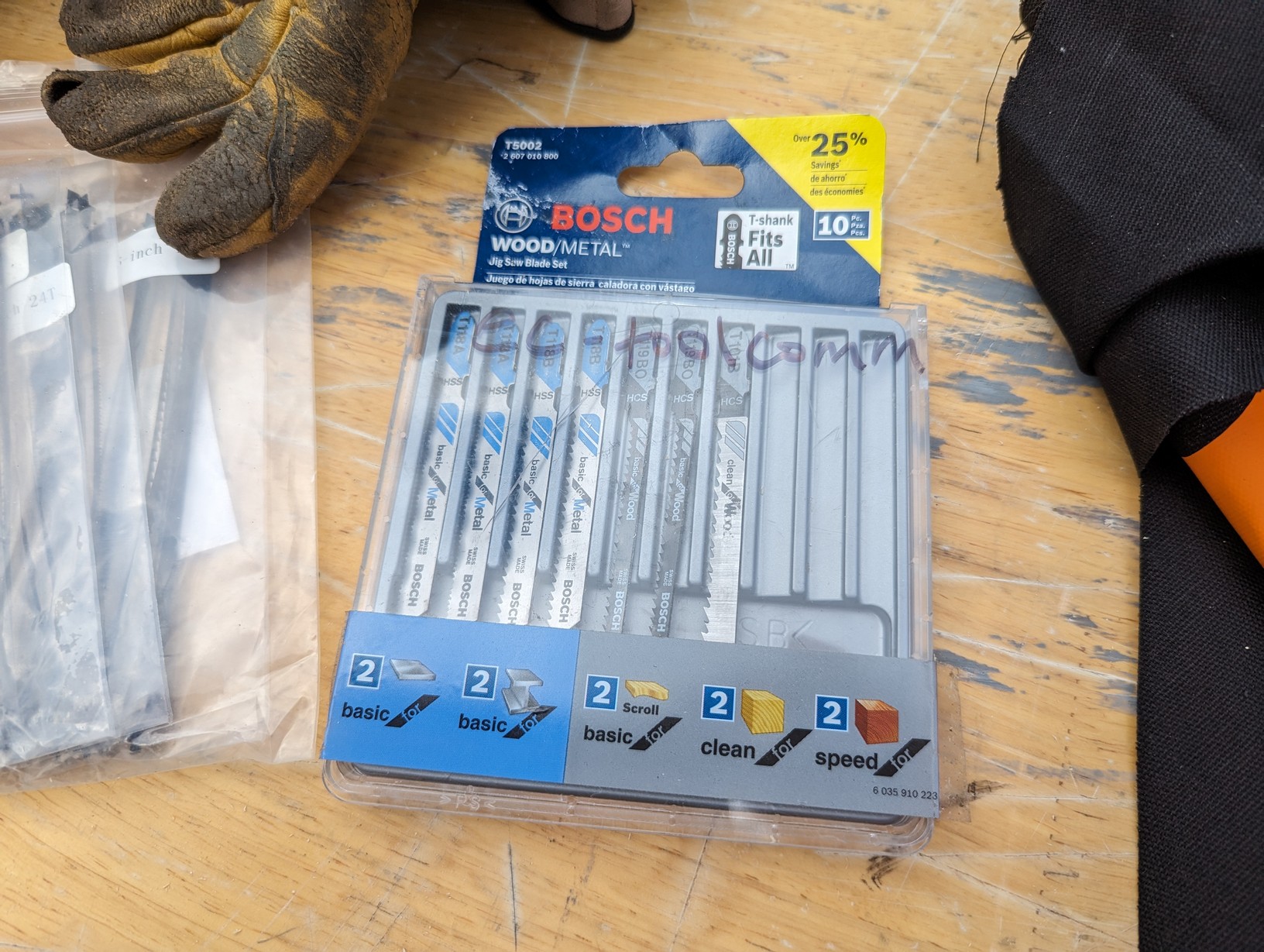

Some things don’t need as much time or effort as much as someone with the right know-how in the right place. At some point, we needed to switch out the jigsaw blades. I was the only one on-site with any experience maintaining jigsaws, so that was on me to swap out and quality-test the jigsaws to make sure they were still fit for construction.

One of the days, we needed to continue spray painting the steel plates we had. Each coat needs time to dry, so I got there early one day and did a couple coats. These would go into this year’s iteration of wAo, managed by Lili. Some of the coats were meant to protect the steel from corrosion.

My dear friend Kat Jander ‘25 was on the lighting team and needed some extra hands assembling and transporting her awesome cannonball letters, so I left the build site for a few hours to help her with that. She had already done all the design work and production work in the months before, but the project just needed some tedious screwing things together to get it across the finish line.

East Side Party

The deadline for construction is the night of the East Side Party, where one or several EC residents DJ from the third floor of the fort. All students are invited to hang out, dance, and see the product of the builders’ hard work. It’s also a time when we run the rides like Space Trainer and wAo, and open up the climbing wall.

I think it’s meant to kick off REX, where dorms host a bunch of cool events to welcome the first-years. I was an orientation leader in 2021, and I could swear that the attendance of the East Side Party that year was far higher than any orientation event. And this is happening before most upperclassmen are invited back to campus.

During the East Side Party this year, I accompanied my friends who were watching the climbing wall to make sure things were staying safe during the event.

Deconstruction

On my last full day in Cambridge, I helped out for a little bit in the morning and a few hours at night in the deconstruction effort. It was the day before Registration Day, and the team (especially hardworking Jordan P.A.) was getting stressed out that not very much progress was being made on deconstruction. It would be even harder to work on getting the build down once classes start, so Registration Day was a soft deadline.

The people who were showing up were working very hard, but there was severe difficulty getting people to show up. It’s been true even in the best of times, like in previous years when our target audience lived right next to the build site. But now, volunteers would need to actively show up, and not many did.

I remember being very involved in deconstruction last year in 2022, and it was the exact same situation as this year: the build group chat would have 100 people, and frequent desperate bumps, and less than six people (and the same six people!) would show up every day to help out. The difference was that then, I could see the lurkers through their bedroom windows from the courtyard. Now, they were just out of sight.

Maybe things were different before the pandemic. I don’t think this pattern is sustainable. A spectacle of a community’s labor needs a community’s labor. There needs to be major overhaul in assessing or cultivating interested student labor in seeing the project through, or the project needs to be downscaled or shelved. Of course, it’s harder when the dorm is under renovation.

I always thought it was weird how soon we need to deconstruct. The full build would only be up for a few days to a week. Maybe it’s just been the case these past few post-pandemic years, and maybe in earlier years the builds would be up for longer. I don’t know. But the designs go through so much review, and the build takes so long, that it feels a bit like a waste that the builds have to go down so quickly.

The build uses more-or-less the same techniques as typical American wooden-frame houses do. I suspect (with absolutely zero education in mechanical engineering) that the structure could stand safely for months, if not years, with how large the safety margins are. It seems like a lot of overengineering for something that comes up and comes right back down. I get needing to take it down this year because we were using borrowed fields, but I feel like they could stay up just fine in the East Campus courtyard. Maybe it’s the Institute’s fear of liability or something.

I suppose it’s not so different than running a school play. Professional actors doing Broadway shows rehearse for months and do eight shows a week for months and months afterward. For school plays, actors have a couple months of (part time) rehearsal for a handful of shows, and then it’s all over. Both EC build and school plays have that bizarre ratio between preparation and runtime.

It’s probably not a controversial take that the EC build is more for the spectacle than it is for the structure itself.

Disposal

There’s a step that comes after deconstruction.

Usually after deconstruction, the builders and other EC residents salvage some of the lumber for their own projects. Most typical is the loft, which you might see in my room tour or other people’s posts. At some point I’ll write a more comprehensive post about my experience with my salvaged wood in 2022.

All the wood that remains after salvage (which this year was quite a lot, considering there was no East Campus in which to squirrel away all the wood) is taken for disposal.

-

The pandemic that shut down 2020 notwithstanding. ↩

-

Here’s an article of a previous build from 2016, though it also mentions Next Haunt, which is something Next House does. See also EC Build 2014. ↩

-

Anhad is a genius. He’s going to change the world one day. ↩